BLOWDOWN IN GAUGE GLASSNORMAL BLOWDOWNCROSS BLOW DOWN PROCEDURE(PART3) YouTube

Gauge Glass Basics. 143 McDonough arkway, McDonough, GA 30253 www.boilersupplies.com (800) 80-3776 pg.2. Gauge Glass Basics. A gauge or sight glass is a clear glass tube connected between the top. and bottom of a boiler or other pressurized liquid tank. It is connected such that the level of the liquid in the sight glass is equal to the liquid.

Know The Procedure For Boiler Gauge Glass Blow Through Marine Engineers Knowledge vlr.eng.br

Proper blow through of gauge glass is to be carried out at frequent intervals and if any doubt existsabout the accuracy of the reading indicated by the gauge.

Boiler Gauge Glass Blowdown Procedure Explained saVRee

#marineboiler #blowthroughprocedurecredits - Adu Academy

Boiler Gauge Glass Blow Through Procedure 3D Animated Explanation YouTube

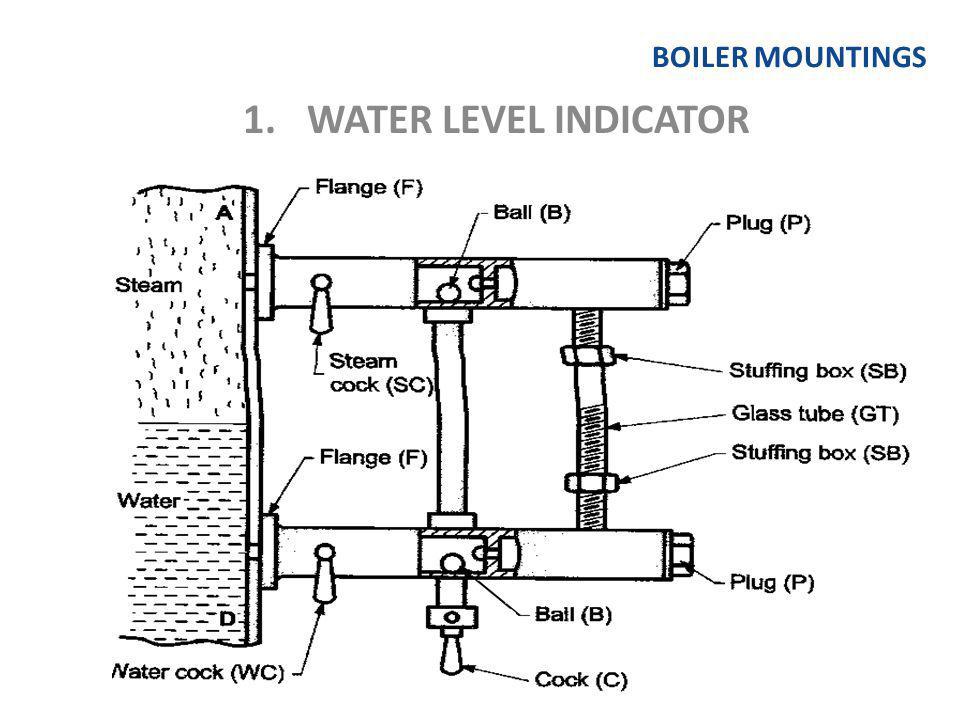

Open cock 'S' and blow through. Make sure that steam is coming out and cock 'S' is clear. Close steam cock. Close drain 'D'. Open water cock 'W' and check water level rises in the glass. Open steam cock 'S' for showing boiler water level. The glasses should be kept clean. The glands should be nipped up at the first sign of.

HVAC 1/2" BOILER SIGHT GAUGE GLASS COMPLETE SET KIT WITH 5/8" X 12" GLASS eBay

Procedure for Blowdown of Boiler Guage Glass. > Close water cock and steam cock of gauge glass and open the drain. > Open the steam cock a strong jet of steam should be seen from the drain after that close the steam cock. > Open the water cock a strong jet of water should be seen from the drain after that close the water cock and drain. > Open.

Know the procedure for boiler gauge glass blow through Marine engineers knowledge

Boiler Blow Down OR Blow Through Procedure • shut steam side• Shut water side• open the drain at the bottom then gauge glass becomes empty.• then open the.

Round Reflex boiler water level gauge glass, Color Transparent at Rs 159 / Piece in Bhuj

Putting the gauge glass in normal operating position. Close all the valves S, W and the drain valve D. Now open the cock W and let the water fill inside the gauge glass. Now open the cock S and then the level can be seen as the pressure equalizes. Disclaimer :The information contained in this website is for general information purposes only.

quick open boiler Reflex Glass Level Gauge level gauge

Blow through of gauge glass should be carried out on daily basis. First shut the steam side. Second shut the water side. Open the drain cock at the bottom. Now wait till gauge glass became empty. Open the steam side, let the steam drains and clears the steam side. Close the steam side and open the water side, let the water drains completely and.

Boiler Gauge Glass Blowdown Procedure Explained saVRee

Close the drain valve. Open the water valve slowly and the gauge glass will begin to fill. When the water valve is fully open, open the steam valve slowly. The water level in the boiler gauge glass will settle to the same level as that in the boiler. In some systems, double valve isolations are provided, however, the procedure remains the same.

Steam Boiler Sight Glass How to use the sight gauge to set the water level steam boiler

If the water cock is open and steam cock closed water from the boiler will channel into the gauge glass and fill indicating a false high water level. Since there is no steam inlet to the gauge class a differential pressure is set up between the water in the boiler and that in the gauge glass .

EX10 Boiler Gauge Glass Blow Through PDF

Boiler [Part 2], Water Level Indicator (Gauge Glass) Marine Boiler. Marine boiler water level indicator regulations, type of gauge glass, tubular type water gauge glass, boiler gauge glass overhaul procedure, safeties of boiler gauge glass, procedure for blow through of boiler Gauge Glass on Ships, cross blowing.

Boiler Gauge Glass and Boiler Fittings SY Befur

2.Draining the Gauge Glass: Open the drain valve to empty the water from the sight glass. If nothing comes out after opening the drain, it indicates both steam and water valves are closed properly. 3.Clearing the Steam Side: Open the steam valve cautiously and allow steam to blow through the gauge glass for a short time, clearing any blockage.

Boiler Gauge glass Operation and SOP Thermal Power Tech

Hello,In this video I will be explaining you about the procedure to follow for blow through of boiler gauge glass.Recommended Blowdown Procedure for Boiler L.

BOILER GAUGE GLASS BLOWDOWN PROCEDURE TAMIL KARAN DESINGU YouTube

Water gage glasses continue to be a vital instrument on power boilers that are constructed to comply with the requirements of the American Society of Mechanical Engineers' (ASME's) Boiler and Pressure Vessel Code. The code requires that all boilers must be equipped with at least one water gage glass for good reason in addition to the other level-indicating instruments operators rely upon.

Boiler Gauge Glass Blow Through Procedure YouTube

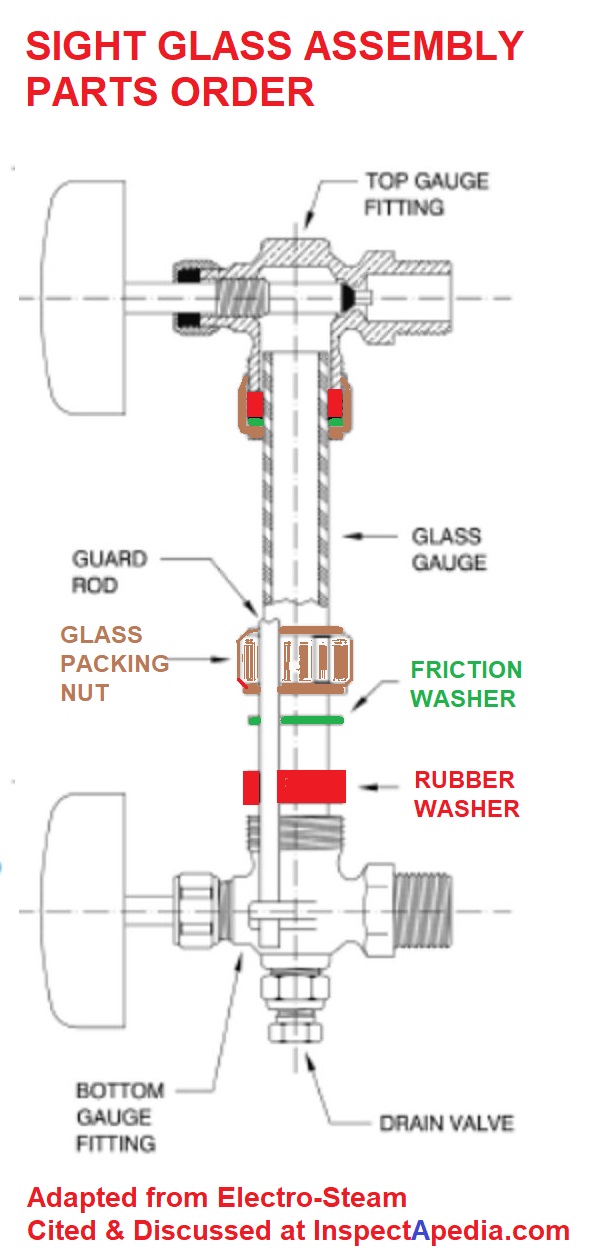

The double plate type gauge glass is held under compression using a nut and bolt arrangement. The glass pieces sit upon joints and a mica sheet separates the glass from the water/steam. Due to the elevated pressures and temperatures the double plate type glass plates are exposed to, it is necessary to add a mica sheet between the glass and.

Boiler gauge glass blow through procedure? REFINERY OIL AND GAS

Open the water cock side, blow out the water. Close the water cock side, the water connection is clear. Close the drain cock. Open the water cock, water should then gradually come rise up to the top of the gauge glass. Open the steam cock, the water in the glass should fall to the level of the water in the boiler.